We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

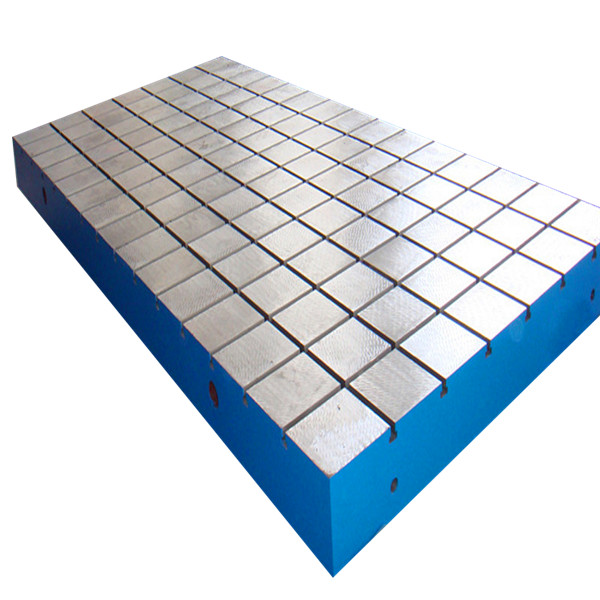

Image Credits: kwanchai/shutterstock.com Cast Iron T-Slotted Plate

AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. It has a tensile strength of 570 - 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition.

AISI 1045 steel has a low through-hardening capability with only sections of around 60 mm in size being recommended as suitable for tempering and through-hardening. However, it can be efficiently flame- or induction-hardened in the normalized or hot rolled condition to obtain surface hardnesses in the range of Rc 54 - Rc 60 based on factors such as section size, type of set up, quenching medium used etc.

AISI 1045 steel lacks suitable alloying elements and hence does not respond to the nitriding process.

AISI 1045 steel has good machinability in a normalized or hot-rolled condition. Based on the recommendations given by the machine manufacturers, operations like tapping, milling, broaching, drilling, turning and sawing can be carried out on AISI 1045 steel using suitable feeds, tool type, and speeds.

AISI 1045 steel is readily welded when the correct procedure is followed, but welding AISI 1045 steel in through-hardened, tempered and flame- or induction-hardened conditions is not recommended. Low hydrogen electrodes are preferred for welding AISI 1045 steel.

AISI 1045 is subjected to forging, annealing, normalizing, stress-relieving, hardening and tempering processes – each of which is explained in more detail below:

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength. Typical applications of AISI 1045 are as follows:

This article was updated on 7th August, 2019.

I want to mfg A105 flanges which rod should i use?

Can this steel be hot-dip galvanized? I will be using it as a structural pin in an outdoor industrial environment.

The opinions expressed here are the views of the writer and do not necessarily reflect the views and opinions of AZoM.com.

Do you have a review, update or anything you would like to add to this article?

In this interview, News Medical speaks with John Weaver from Pfizer about the importance of process safety testing.

In this interview, AZoM speaks to Bruker Optics about the different ways IR light can be used in semiconductors.

At The Greener Manufacturing Show 2023, we spoke with KUORI CEO and Founder Sarah Harbarth about the growth and ambitions of the company as it develops its novel materials.

Specac’s Power Hydraulic Press Series are available in 8 Ton, 15 Ton and 25 Ton load configurations.

The SamplerSight Pharma from PMS is an easy-to-use software for batch sampling.

Allectra's latest bimetallic CF component series, featuring innovative Titanium CF Flanges linked with Aluminum Tubes, promises to revolutionize the design of Aluminum chambers.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

Cast Iron Surface Plate Factory Owned and operated by AZoNetwork, © 2000-2023