Understanding the challenge posed by silica dust exposure on site and in confined spaces, and the comprehensive standards and measures used to combat its peril.

Approximately 2.3 million workers in the United States are exposed to Respirable Crystalline Silica (RCS) or silica dust every year, which is now known to possess a similar magnitude of risk as the more widely understood asbestos dust. Crystalline silica is found in many commonly used construction materials, including sand, gravel, clay, stones, concrete, bricks and quartz. When these materials are broken, stirred or otherwise disturbed through cutting, drilling, grinding or crushing, minuscule dust particles are created. When inhaled, these particles travel deep into the lungs and can cause incurable and sometimes deadly respiratory diseases such as silicosis, chronic obstructive pulmonary disease and kidney disease. Ultra Low Dust Concentration Detector

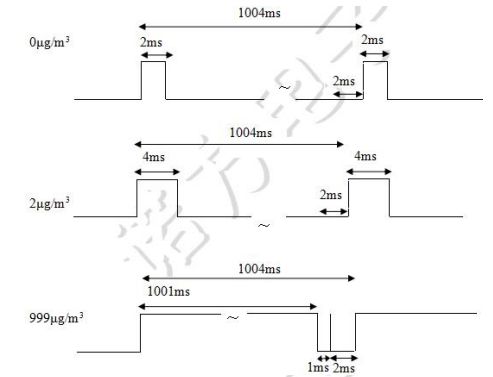

The Department of Labor has recently (June 2023) proposed a new ruling to limit silica dust exposure by its Mine Safety and Health Administration (MHSA) to better protect miners’ health. This comes almost exactly ten years after The Occupational Safety and Health Administration (OSHA) proposed a rule aimed at curbing workers’ exposure to crystalline silica across all industries by updating the Permissible Exposure Limit (PEL) to be in line with modern understanding of the hazard. The newest proposal by the MHSA would see the PEL of silica dust at or below 50μg/m3 (micrograms per cubic meter of air) for a full shift of exposure, equal to an eight-hour time-weighted average. For reference, the PEL of any hazardous dust in the workplace is ten milligrams per cubic meter.

As with any known workplace health risk, the most effective means of reducing worker exposure to respirable crystalline silica is a correctly implemented scheme of controls using the hierarchy of controls. This can help reduce both the likelihood of workers developing health complications such as silicosis and the potential legal ramifications for employers. Measures include a correctly executed program of air monitoring, which can include both monitoring at the site level and on an individual employee level using personal sampling pumps. Air monitoring can quantify exposure levels, or if controls are in place, check that they are effective and measure any residual risk. These pumps are essential in places where there is a significant risk of highly concentrated hazardous pollutants in the surrounding air, for example, confined spaces and sites that emit large quantities of fumes.

In controlling dust, the usual risk control hierarchy applies. Where the risk cannot be eliminated entirely, a safer form of the product should be used. If this is not feasible, the process should be changed to emit less dust or enclose the process so that the dust does not escape or by extracting the dust near the source using local exhaust ventilation (LEV). Employers should make the process efficient enough to have as few workers in harm’s way as possible. In the hierarchy of control, the last thing you apply is respiratory protection. Often, because of poor understanding of toxicity and dust concentration, the wrong respiratory protection is used.

This article originally appeared in the October 2023 issue of Occupational Health & Safety.

According to the National Safety Council, work-related medically consulted injuries total 4.26 million in 2021 in USA alone. SOL-X solution prevents “human factors” safety issues by anticipating incidents and improving compliance workflows. Leverages digital technologies (IIoT, AI and analytics) to predict patterns from occurring and make informed decisions. Control Of Work - gets rid of tedious paperwork and experience digital workflows. Crew Protect - maximises safety and situational awareness with health trackers and situational indicators. Award-winning Intrinsically Safe SmartWatch – innovative features that enable near real-time visibility and connected well-being. Works well with major connectivity protocols like Wi-Fi, Bluetooth, and Long-Range Bluetooth! 3

The MGC Simple Plus is a simple-to-use, portable multi-gas detector that runs continuously for three years without needing to be recharged or routinely calibrated after its initial charge and calibration during manufacturing. The detector reliably tests a worksite’s atmosphere for hydrogen sulfide, carbon monoxide, oxygen and combustible gases (LEL). Additionally, it is durable enough to withstand the harshest treatment and environments, which is why it has an IP 68 rating. The MGC Simple Plus is also compatible with a variety of accessories, such as Gas Clip Technologies’ new GCT External Pump. Visit gascliptech.com for more information. 3

The new MSA V-SHOCK EDGE Cable SRLs and Web PFLs for Leading Edge use are designed for simplicity and hassle-free safety. V-SHOCK EDGE solutions help make PPE selection on the jobsite quick and easy with color-coded housings, clear icons on labels, and clearance charts in the label pack. 3

Regardless of changing conditions, employers have a responsibility to make sure their workers are well-prepared for the risks their roles may pose. Read Now

As demonstrated by successful organizations across the globe, a safe work culture benefits every area of a business. Read Now

Wagner Construction Inc. repeatedly exposed workers to trenching hazards. Read Now

Using a computerized maintenance management system helps with costs and efficiency but also improves safety and reduces environmental impact. Read Now

Four serious accidents tied to such equipment happened in a matter of weeks. Read Now

Dust Monitoring Instruments And Equipment See our Privacy Policy, Cookie Policy and Terms of Use. CA: Do Not Sell My Personal Info